Product Details Page

Product Catalog

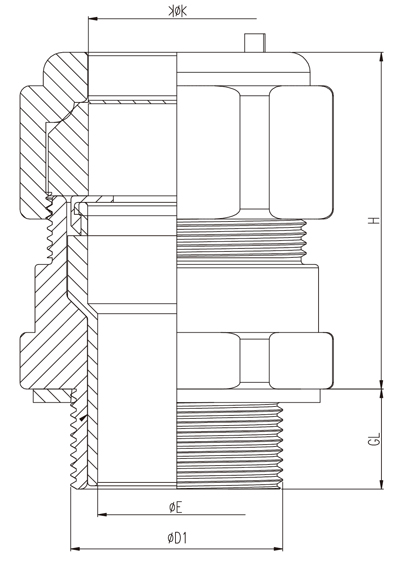

Metric and NPT Type Single Sealing Filling Exd Cable Gland

- Material: Nickel-plated Brass

- Seal: Beisit solo elastomer for Exd cable glands

- Gasket: High Stable PA Material

- Working Temperature: -60~130℃

- Certificate Testing Temperature: -65~150℃

- Design Specification: IEC62444, EN62444

- IECEx Certificate: IECEx TUR 20.0079X

- Certificate: TÜV 20 ATEX 8609X

- Code of Protection: I M2 Ex db I Mb/Ex eb I Mb

II 2 G Ex db IIC Gb/Ex eb IIC Gb/Ex nR IIC Gc

II 1 D Ex ta IIIC Da IP66/68(10m 8h) - Standards: IEC60079-0,1,7,15,31

- CCC Certificate: 2021122313114717

- Conformity Certificate of Ex-proof: CJEx21.1189U

- Code of Protection: Exd ⅡCGb;ExtDA21IP66/68(10m 8h)

- Standards: GB3636.0, GB3836.1, GB3836.2, GB12476.1, GB12476.5

- Cable Type: Non-armoured & Braided Cable

- Material options: HPb59-1、H62、304、316、316L can be offered

(1) 2 filling method for barrier; (2) Anti-slip design; (3) The same specification, the same wrench size; (4) Complete specifications and models; (5) IP68 10m/8h; (6) Loading test diameter 20 times (100% pull); (7) Hydrostatic test 30bar.

Metric Type Single Sealing Filling Exd Cable Gland

| Thread(φD1) | Cable range(mm) |

Cable Core Qty |

Max.Dia.of |

E(mm) |

H(mm) |

GL(mm) |

Wrench Size(mm) |

Beisit No. |

| M16X1.5 | 3.0-8.0 |

6 |

6.8 |

8.5 |

45 |

15 |

24 |

BST-Exd-SSF-M1608BR |

| M20X1.5 | 3.0-8.0 |

6 |

10 |

12.5 |

42 |

15 |

24 |

BST-Exd-SSF-M2008BR |

| M20X1.5 | 7.5-12.0 |

6 |

10 |

12.5 |

42 |

15 |

24 |

BST-Exd-SSF-M2012BR |

| M20X1.5 | 8.7-14.0 |

10 |

9.8 |

12.3 |

41 |

15 |

27 |

BST-Exd-SSF-M2014BR |

| M25X1.5 | 9.0-15.0 |

21 |

13.4 |

16.8 |

51 |

15 |

36 |

BST-Exd-SSF-M2515BR |

| M25X1.5 | 13.0-20.0 |

21 |

13.4 |

16.8 |

51 |

15 |

36 |

BST-Exd-SSF-M2520BR |

| M32X1.5 | 19.0-26.5 |

42 |

18.9 |

23.7 |

51 |

15 |

43 |

BST-Exd-SSF-M3227BR |

| M40X1.5 | 25.0-32.5 |

60 |

24.8 |

31 |

53 |

15 |

50 |

BST-Exd-SSF-M4033BR |

| M50X1.5 | 31.0-38.0 |

80 |

30.8 |

38.5 |

61 |

15 |

55 |

BST-Exd-SSF-M5038BR |

| M50X1.5 | 36.0-44.0 |

80 |

32.8 |

41.1 |

63 |

15 |

60 |

BST-Exd-SSF-M5044BR |

| M63X1.5 | 41.5-50.0 |

100 |

41.6 |

52 |

66 |

15 |

75 |

BST-Exd-SSF-M6350BR |

| M63X1.5 | 48.0-55.0 |

100 |

41.6 |

52 |

66 |

15 |

75 |

BST-Exd-SSF-M6355BR |

| M75X1.5 | 54.0-62.0 |

120 |

52.3 |

65.4 |

63 |

15 |

90 |

BST-Exd-SSF-M7562BR |

| M75X1.5 | 61.0-68.0 |

120 |

52.3 |

65.4 |

63 |

15 |

90 |

BST-Exd-SSF-M7568BR |

| M80X2.0 | 67.0-73.0 |

140 |

56.4 |

70.5 |

82 |

24 |

96 |

BST-Exd-SSF-M8073BR |

| M90X2.0 | 66.6-80.0 |

140 |

62.9 |

78.7 |

80 |

24 |

108 |

BST-Exd-SSF-M9080BR |

| M100X2.0 | 76.0-89.0 |

200 |

70.9 |

88.7 |

98 |

24 |

123 |

BST-Exd-SSF-M10089BR |

NPT Type Single Sealing Filling Exd Cable Gland

| Thread(φD1) | Cable range(mm) |

Cable Core Qty |

Max.Dia.of |

E(mm) |

H(mm) |

GL(mm) |

Wrench Size(mm) |

Beisit No. |

| NPT1/2 " | 3.0-8.0 |

6 |

10 |

12.5 |

42 |

19.9 |

24 |

BST-Exd-SSF-N1208BR |

| NPT3/4 " | 3.0-8.0 |

6 |

10 |

12.5 |

42 |

19.9 |

27 |

BST-Exd-SSF-N3408BR |

| NPT1/2 " | 7.5-12.0 |

6 |

10 |

12.5 |

42 |

19.9 |

24 |

BST-Exd-SSF-N1212BR |

| NPT3/4 " | 7.5-12.0 |

6 |

10 |

12.5 |

42 |

19.9 |

27 |

BST-Exd-SSF-N3412BR |

| NPT1/2 " | 8.7-14.0 |

10 |

9.8 |

12.3 |

41 |

19.9 |

27 |

BST-Exd-SSF-N1214BR |

| NPT3/4 " | 8.7-14.0 |

10 |

9.8 |

12.3 |

41 |

19.9 |

27 |

BST-Exd-SSF-N3414BR |

| NPT3/4 " | 9.0-15.0 |

21 |

13.4 |

16.8 |

51 |

20.2 |

36 |

BST-Exd-SSF-N3415BR |

| NPT3/4 " | 13.0-20.0 |

21 |

13.4 |

16.8 |

51 |

20.2 |

36 |

BST-Exd-SSF-N3420BR |

| NPT1 " | 9.0-15.0 |

21 |

13.4 |

16.8 |

51 |

20.2 |

36 |

BST-Exd-SSF-N10015BR |

| NPT1 " | 13.0-20.0 |

21 |

13.4 |

16.8 |

51 |

20.2 |

36 |

BST-Exd-SSF-N10020BR |

| NPT1 " | 19.0-26.5 |

42 |

19 |

23.7 |

51 |

25 |

43 |

BST-Exd-SSF-N10027BR |

| NPT1 1/4 " | 19.0-26.5 |

42 |

19 |

23.7 |

51 |

25 |

43 |

BST-Exd-SSF-N11427BR |

| NPT1 1/4 " | 25.0-32.5 |

60 |

24.8 |

31 |

53 |

25.6 |

50 |

BST-Exd-SSF-N11433BR |

| NPT1 1/2 " | 25.0-32.5 |

60 |

24.8 |

31 |

53 |

25.6 |

50 |

BST-Exd-SSF-N11233BR |

| NPT2 " | 31.0-38.0 |

80 |

30.8 |

38.5 |

61 |

26.1 |

70 |

BST-Exd-SSF-N20038BR |

| NPT2 " | 35.6-44.0 |

80 |

32.9 |

41.1 |

63 |

26.6 |

70 |

BST-Exd-SSF-N20044BR |

| NPT2 1/2 " | 35.6-44.0 |

80 |

32.9 |

411 |

63 |

29.9 |

80 |

BST-Exd-SSF-N21244BR |

| NPT2 1/2 " | 41.5-50.0 |

100 |

41.6 |

52 |

66 |

26.9 |

80 |

BST-Exd-SSF-N21250BR |

| NPT2 1/2 " | 48.0-55.0 |

100 |

41.6 |

52 |

66 |

39.9 |

80 |

BST-Exd-SSF-N21255BR |

| NPT3 " | 48.0-55.0 |

100 |

41.6 |

65.4 |

66 |

39.9 |

96 |

BST-Exd-SSF-N30055BR |

| NPT3 " | 54.0-62.0 |

120 |

52.3 |

65.4 |

63 |

39.9 |

96 |

BST-Exd-SSF-N30062BR |

| NPT3 " | 61.0-68.0 |

120 |

52.3 |

65.4 |

63 |

41.5 |

96 |

BST-Exd-SSF-N30068BR |

| NPT3 1/2 " | 61.0-68.0 |

120 |

52.3 |

70.5 |

63 |

41.5 |

108 |

BST-Exd-SSF-N31268BR |

| NPT3 " | 67.0-73.0 |

140 |

56.4 |

70.5 |

82 |

41.5 |

96 |

BST-Exd-SSF-N30073BR |

| NPT3 1/2 " | 67.0-73.0 |

140 |

56.4 |

70.5 |

82 |

41.5 |

108 |

BST-Exd-SSF-N31273BR |

| NPT3 1/2 " | 66.6-80.0 |

140 |

63 |

78.7 |

80 |

42.8 |

108 |

BST-Exd-SSF-N31280BR |

| NPT4 " | 66.6-80.0 |

140 |

63 |

78.8 |

80 |

42.8 |

123 |

BST-Exd-SSF-N40080BR |

| NPT3 1/2 " | 76.0-89.0 |

200 |

71 |

88.7 |

98 |

42.8 |

123 |

BST-Exd-SSF-N31289BR |

| NPT4 " | 76.0-89.0 |

200 |

71 |

88.7 |

98 |

42.8 |

123 |

BST-Exd-SSF-N40089BR |

Introducing our revolutionary single seal filled Exd cable gland - the ultimate solution for safe and efficient cable management. Designed with precision engineering and advanced technology, this cable gland is an industry game changer. Our single seal filled Exd cable glands are specifically designed to provide a safe and secure seal for cables in hazardous environments. It provides unparalleled protection against dust, water and gas, ensuring the highest level of security for your electrical connections. With its excellent sealing properties, this cable gland is ideally suited for applications in industries such as oil and gas, petrochemical, mining and marine.

One of the outstanding features of our single seal filled Exd cable glands is their innovative single seal system. Unlike traditional glands that use multiple seals, our glands feature a single sealing mechanism that simplifies the installation process while maintaining superior performance. This not only reduces assembly time but also minimizes the risk of seal failure. In addition to an advanced sealing system, our single seal filled Exd cable glands are equipped with an innovative filling compound. This compound automatically seals around the cable, providing an extra layer of protection against moisture and contaminants. The filler compound also provides excellent strain relief and vibration resistance, ensuring the longevity and reliability of cable connections even in the most demanding environments.

Additionally, our single seal-filled Exd cable glands have a rugged construction. It is made of high-quality materials and is extremely durable and able to withstand harsh conditions. Its corrosion-resistant properties make it suitable for both indoor and outdoor applications. Our team of experts have conducted extensive testing on single seal filled Exd cable glands to ensure they comply with international safety standards. It meets all requirements for explosion-proof and fire-proof applications, giving you peace of mind about the safety of your electrical connections. Overall, the single seal filled Exd cable gland is an unrivaled solution for cable management in hazardous environments. Its superior sealing performance, innovative single sealing system and durable construction make it the perfect choice for industries where safety is critical. Invest in our single seal-filled Exd cable glands today and experience new levels of reliability and efficiency in your cable installations.