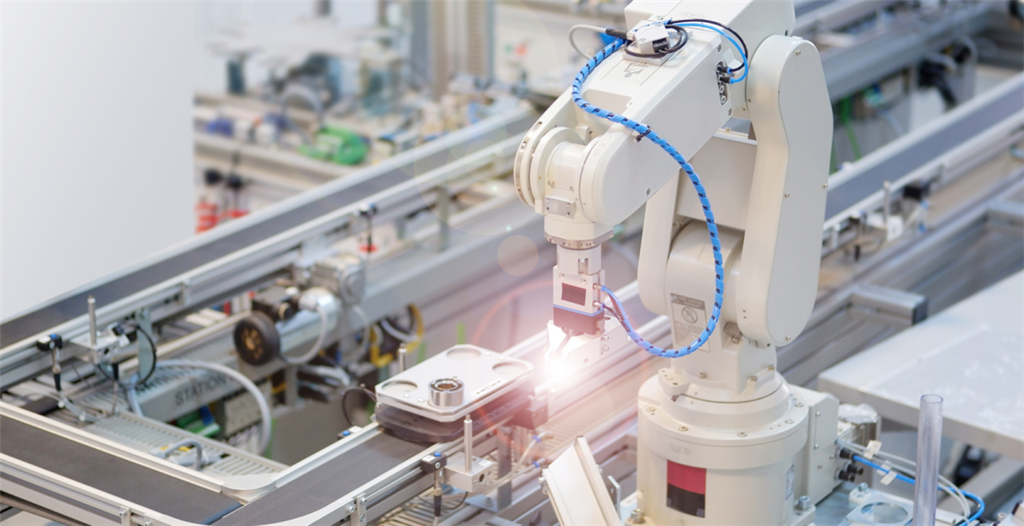

In the context of the accelerated implementation of Industry 4.0 and intelligent manufacturing, precise interconnection and real-time data interaction between devices have become core requirements. The Beisit M12 circular connector, with its compact design, high reliability, and environmental adaptability, has become an indispensable key component in the field of industrial automation, providing efficient transmission support for the "nervous system" of smart factories.

Professional performance advantage: Technology empowers intelligent manufacturing

The Beisit M12 connector strictly follows the IEC 61076-2 international standard to ensure compatibility and interchangeability with mainstream devices worldwide. Its core advantages are reflected in:

High protection and durability: The entire series of products achieve IP67 protection level, which can resist dust intrusion and short-term water immersion; Through 96 hours of salt spray testing, the equipment is adapted to corrosive environments such as chemical and marine environments, ensuring stable operation at extreme temperatures ranging from -40 ℃ to+85 ℃.

Anti vibration and signal integrity: Adopting an integrated bayonet locking structure and gold-plated/silver plated contact design, it can maintain a contact resistance of ≤ 10m Ω even in harsh scenarios with vibration frequencies ranging from 10Hz to 500Hz, ensuring zero packet loss in signal transmission and zero loss in power transmission.

Modular expansion capability: Supports 3-12 core multi type interfaces (such as D-code sensor interfaces, A-code power interfaces), can integrate RJ45, fiber optic and other hybrid transmission solutions, and meet the composite needs of data, power and other aspects in industrial IoT.

Industry application scenario: driving the entire process of intelligent production

In the intelligent manufacturing system, the application depth and breadth of Beishide M12 connectors continue to expand:

Intelligent equipment interconnection: As a standard interface for industrial robot joint motors and servo drives, it ensures real-time transmission of high-frequency motion control signals and supports high-precision operations of collaborative robots.

Industrial network architecture: In the 5G+TSN (Time Sensitive Network) factory, M12 connectors build high-speed Ethernet links from the device layer to the control layer, helping digital twins interact with edge computing with low data delay.

Flexible production system: adapted to AGV (Automated Guided Vehicle) charging stations and three-dimensional storage sensor networks, achieving seamless connection and dynamic response of material handling systems, and improving the efficiency of production line changeover.

Customized Services: Born for Intelligent Manufacturing Scenarios

In response to personalized customer needs, Beishide provides customized solutions from interface types, cable materials to protection levels. The M12 circular connector is not only a physical connection point for industrial equipment, but also a strategic pivot for intelligent upgrading. With its technological strength and scenario based innovation, it continues to promote industrial automation towards high reliability and flexibility, providing underlying support for the construction of the global intelligent manufacturing ecosystem.

Post time: Feb-21-2025